News

-

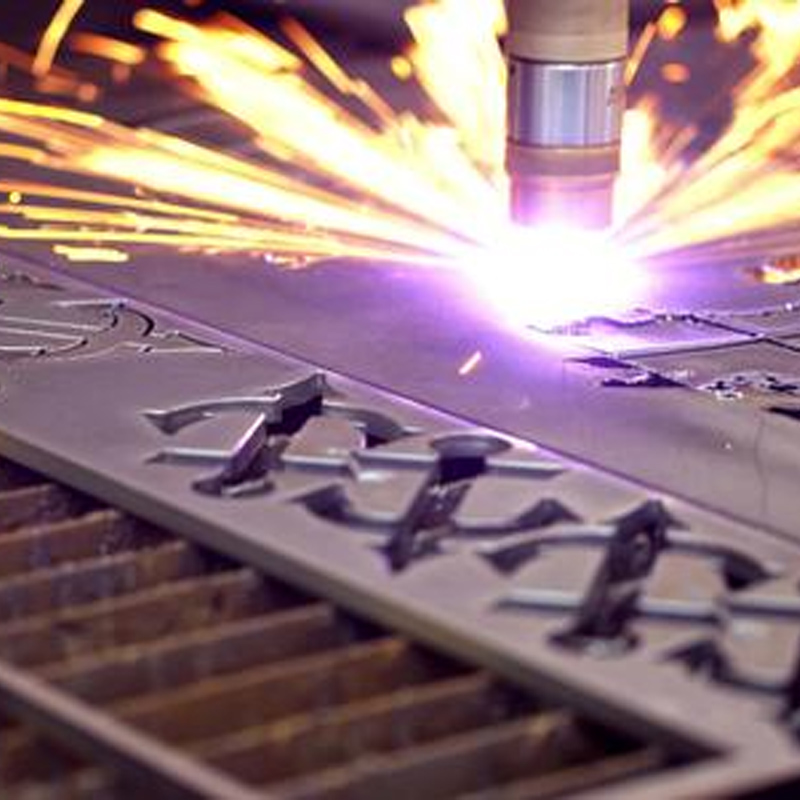

Stainless steel casting process

Stainless steel casting is not only suitable for casting of various types and alloys, but also produces castings with higher dimensional accuracy and surface quality than other casting methods. Even casting methods that are difficult to ... -

Investment casting

Investment casting, also known as lost wax casting, includes processes such as wax pressing, wax repairing, tree formation, dip slurry, melting wax, casting molten metal, and post-treatment. Lost wax casting is to use wax to make the wax... -

The difference between normal milling and reverse milling in milling

Climb milling: It means that the cutting speed direction of the tool is the same as the moving direction of the workpiece.Up milling: It means that the cutting speed of the tool is opposite to the moving direction of the workpiece.Second... -

Features of down milling and up milling

1. Climbing: The rotation direction of the milling cutter is the same as the feed direction of the workpiece.Range of down milling: When there is no hard skin on the surface of the workpiece and there is no gap in the feed mechanism of t... -

What factors affect the density of stainless steel castings?

1. Development of castings2. The precision of mold design, processing and production and the use of mold materials3. Shrinkage of raw materials for castings4. Establishment and implementation of casting process -

Main methods of mirror treatment effect in stainless steel precision casting

In the production process of stainless steel precision casting, its sulfuric acid oxide film is an important factor affecting the high purity and transparency of its stainless steel casting oxide film. The porosity, purity, thickness and...